+49 (0) 711 381607

WE SELL ZK 1003 SCREW LOCKING VARNISH

Marking paint

Transport technology

Electronics

Electrical engineering

Sealing

Aeronautical engineering

Energy, wind power

Telecommunications

Locking varnishes

Automotive industry

Mechanical engineering

Precision mechanics

The ZK 1003 screw locking varnish from H. August Müller has been on the market for over 50 years. We supply German and international production sites of small, medium, large and global industrial companies. In all the years that we have been offering our products on the market, we have built up an excellent reputation with our customers through our fast, reliable and impeccable delivery.

Our ZK 1003 screw locking varnish is THE aid for marking and sealing and can be used to detect tampering. ZK 1003 is used on screw, plug and housing connections in the automotive and steel industries, aviation, electronics, mechanical engineering and precision mechanics, among others.

CONTACT

Lackfabrik Bäder GmbH & Co KG

Dieselstraße 34

73734 Esslingen

Germany

Tel: +49 (0) 711 381607

TERMS OF DELIVERY

exworks

Delivery takes place, subject to availability, within 2-3 working days within Germany, within 4-7 working days within the EU, or of course on schedule. Our threadlocker is delivered in a 50g=46ml aluminium tube in its own folding box.

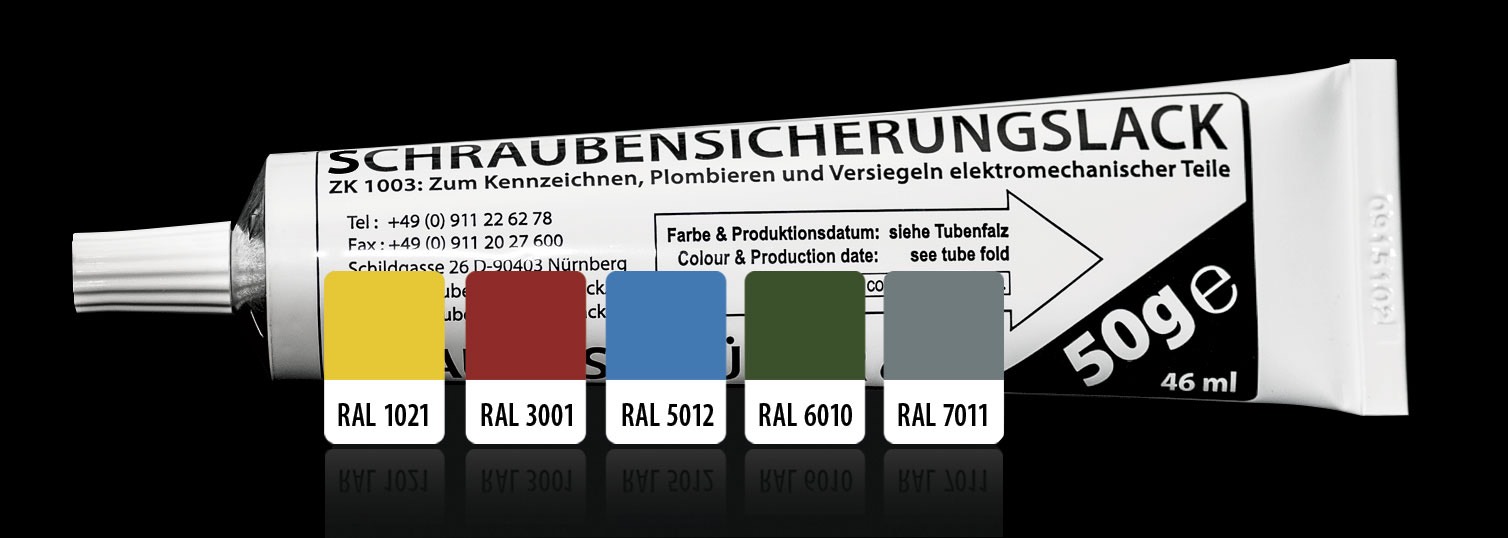

The colour palette for our screw locking varnish

We sell the following colours:

- Screw locking varnish ZK 1003 - rapeseed yellow RAL 1021

- Screw locking varnish ZK 1003 - signal red RAL 3001

- Screw locking varnish ZK 1003 - light blue RAL 5012

- Screw locking varnish ZK 1003 - grass green RAL 6010

- Screw locking varnish ZK 1003 - iron grey RAL 7011

Frequently asked questions

These are the most frequently asked questions by our customers:

Where/how is our paint used?

Areas of application: Our screw locking varnish ZK 1003 is used for labelling, sealing and sealing screws and threads (metal to metal), mainly to prevent tampering with screws or to make it visible. Da das Produkt auf Nitrobasis ist, ist es nicht immer geeignet für: Buntmetalle, Kunststoffe, Kunststoff-Schrauben, Kunststoff-Teile, od. Kunststoff-Gewinde, und sollte im Einzelfall selbst getestet werden.

What is the best way to store the ZK1003?

STORAGE resistance ZK 1003 should be stored in the original container at normal room temperature (10°C to 20°C), provided the original container is tightly closed. Opened containers should be used within a short time. The production date of the respective batch is indicated on the tube seam. Storage beyond the specified period does not necessarily mean that the product is unusable. However, for reasons of quality assurance, it is essential to check the properties required for the respective application and is the responsibility of the purchaser.

For which substrates is the ZK1003 used?

Steel, stainless steel, aluminium, after prior testing: zinc and galvanised substrates Pre-treatment: The substrate must be free of substances that could impair adhesion, e.g. oils, greases and surfactants. We recommend using suitable chemical (e.g. phosphating, chromating) or mechanical (e.g. blasting) pre-treatment methods in accordance with the requirements. Suggested structure: Substrate: steel, top coat: screw locking lacquer ZK 1003, various colours

General processing conditions and drying out

Processing conditions: above 10°C Drying: air drying at 20°C Dust dry: after 20 min. (dryness grade 1/ DIN 53150) Touch dry: after 30 min. (dryness grade 4/ DIN 53150) Through-dried: after 6 days (pendulum damping/ ISO 1522) Oven drying: up to 50°C possible (object temperature) Continuous use temperature: max. 130°C (except for zinc and galvanised substrates)

Temperature resistance of ZK1003 for all colours

In the minus range: After a week of temperature cycling at +20°C (overnight) and -20°C (8 hours during the day) and subsequent storage for 3 weeks at -20°C, we found a slight loss of adhesion. Based on these results, we cannot confirm the temperature resistance down to -20°C and recommend not using the threadlocker below -10°C. In individual cases, separate tests may be necessary, as the type and condition of the substrate and the area of application of ZK 1003 must be taken into account and cannot be simulated in laboratory tests. Continuous service temperature: max. 130°C (except for zinc and galvanised substrates).

Please fill in the form to request a safety data sheet DE.

Thank you for your enquiry. We will be happy to provide you with our current product prices. Please send us an email or fill out the form below. We will contact you shortly.

Lackfabrik Bäder GmbH & Co KG

Dieselstraße 34

73734 Esslingen

Germany

Tel: +49 (0) 711 381607

Customs tariff number: 3208 10 90

LIEFERBEDINGUNG

Delivery will be made, subject to availability, within 2-3 working days within Germany, within 4-7 working days within the EU, or, of course, on schedule.

Our threadlocker is supplied in a 50 g = 46 ml aluminium tube in its own folding box.

SCHRAUBENSICHERUNGSLACK ZK1003

Der Schraubensicherungslack ZK1003 von

H. August Müller ist seit über 50 Jahren auf dem Markt. Wir beliefern deutsche und internationale Produktionsstandorte von kleinen, mittleren, großen und globalen Industrieunternehmen. In all den Jahren, in denen wir unsere Produkte auf dem Markt anbieten, haben wir uns durch unsere schnelle, zuverlässige und tadellose Lieferung einen hervorragenden Ruf bei unseren Kunden aufgebaut. Unser Schraubensicherungslack ZK1003 ist DAS Hilfsmittel zum Markieren und Versiegeln und es können Manipulationen nachgewiesen werden. Der ZK1003 wird unter anderem an Schraub-, Stecker- und Gehäuseanschlüssen in der Automobil- und Stahlindustrie, Luftfahrt, Elektronik, Maschinenbau und Feinmechanik eingesetzt.

We sell the following colours:

Schraubensicherungslack ZK1003 – rapsgelb RAL 1021

Schraubensicherungslack ZK1003 – signalrot RAL 3001

Schraubensicherungslack ZK1003 – lichtblau RAL 5012

Schraubensicherungslack ZK1003 – grasgrün RAL 6010

Schraubensicherungslack ZK1003 – eisengrau RAL 7011

Marking paint

Verkehrstechnik, Elektronik, Elektrotechnik

Sealing

Luftfahrttechnik Energie, Windkraft, Telekommunikation

Locking varnishes

Autoindustrie, Maschinenbau, Feinmechanik

Frequently asked questions

These are the most frequently asked questions by our customers:

Where/how is our paint used?

What is the best way to store the ZK1003?

For which substrates is the ZK1003 used?

Allgemeine Verarbeitungsbedingungen/Austrockung

Temperatur-Beständigkeit von ZK1003 (alle Farben):

Lackfabrik Bäder GmbH & Co KG

Dieselstraße 34

73734 Esslingen

Germany

Tel: +49 (0) 711 381607

Please fill in the form to request a safety data sheet DE.

Thank you for your enquiry. We will be happy to provide you with our current product prices. Please send us an email or fill out the form below. We will contact you shortly.