+49 (0) 711 381607

WIR VERKAUFEN SCHRAUBENSICHERUNGSLACK ZK 1003

Kennzeichnungslack

Verkehrstechnik

Elektronik

Elektrotechnik

Versiegeln

Luftfahrttechnik

Energie, Windkraft

Telekommunikation

Sicherungslacke

Autoindustrie

Maschinenbau

Feinmechanik

Der Schraubensicherungslack ZK 1003 von H. August Müller ist seit über 50 Jahren auf dem Markt. Wir beliefern deutsche und internationale Produktionsstandorte von kleinen, mittleren, großen und globalen Industrieunternehmen. In all den Jahren, in denen wir unsere Produkte auf dem Markt anbieten, haben wir uns durch unsere schnelle, zuverlässige und tadellose Lieferung einen hervorragenden Ruf bei unseren Kunden aufgebaut.

Unser Schraubensicherungslack ZK 1003 ist DAS Hilfsmittel zum Markieren und Versiegeln und es können Manipulationen nachgewiesen werden. Der ZK 1003 wird unter anderem an Schraub-, Stecker- und Gehäuseanschlüssen in der Automobil- und Stahlindustrie, Luftfahrt, Elektronik, Maschinenbau und Feinmechanik eingesetzt.

KONTAKT

Lackfabrik Bäder GmbH & Co KG

Dieselstraße 34

73734 Esslingen

Deutschland

Tel: +49 (0) 711 381607

LIEFERBEDINGUNGEN

exworks

Die Lieferung erfolgt, vorbehaltlich Verfügbarkeit, innerhalb Deutschlands in 2-3 Werktagen, innerhalb der EU in 4-7 Werktagen oder natürlich termingerecht. Unser Schraubensicherungslack wird in einer Alutube 50g=46ml Inhalt in einer eigenen Faltschachtel geliefert.

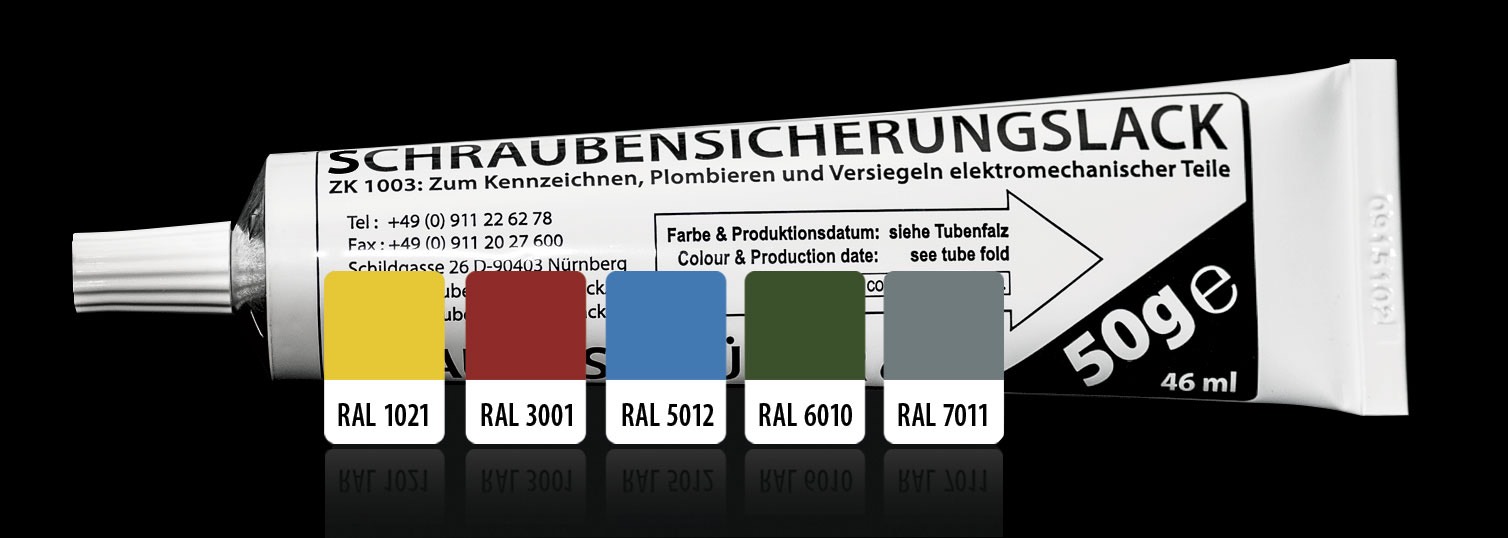

Unsere Farbpalette Schraubensicherungslack

Wir verkaufen folgende Farben:

- Schraubensicherungslack ZK 1003 - rapsgelb RAL 1021

- Schraubensicherungslack ZK 1003 - signalrot RAL 3001

- Schraubensicherungslack ZK 1003 - lichtblau RAL 5012

- Schraubensicherungslack ZK 1003 - grasgrün RAL 6010

- Schraubensicherungslack ZK 1003 - eisengrau RAL 7011

Häufig gestellte Fragen

Das sind die häufigsten Fragen, die unsere Kunden stellen:

Wo/Wie wird unser Lack eingesetzt?

Anwendungsbereiche: Unser Schraubensicherungslack ZK 1003 wird zum Kennzeichnen, Plombieren und Versiegeln von Schrauben und Gewinde (Metall zu Metall) verwendet, hauptsächlich, um eine Manipulation an Schrauben zu verhindern bzw. sichtbar zu machen. Da das Produkt auf Nitrobasis ist, ist es nicht immer geeignet für: Buntmetalle, Kunststoffe, Kunststoff-Schrauben, Kunststoff-Teile, od. Kunststoff-Gewinde, und sollte im Einzelfall selbst getestet werden.

Wie lagert man den ZK1003 am besten?

LAGER-Beständigkeit Der ZK 1003 sollte im Originalgebinde, sofern die Originalgebinde dicht verschlossen sind, bei normaler Raumtemperatur (10°C bis 20°C) gelagert werden. Anbruchgebinde sind kurzfristig zu verarbeiten. Das Herstellungsdatum der jeweiligen Charge ist auf der Tubenfalz angegeben. Eine Lagerung über den angegebenen Zeitraum hinaus bedeutet nicht notwendigerweise, daß die Ware unbrauchbar ist. Eine Überprüfung der für den jeweiligen Einsatzzweck erforderlichen Eigenschaften ist jedoch aus Gründen der Qualitätssicherung unerlässlich und obliegt dem Käufer.

Für welche Untergründe wird der ZK1003 benutzt?

Stahl, Edelstahl, Aluminium, nach vorheriger Prüfung: Zink und verzinkte Untergründe Vorbehandlung: Der Untergrund muß frei von haftungsstörenden Stoffen sein, wie Z.B. Öle, Fette und Tenside. Wir empfehlen den Anforderungen entsprechend geeignete chemische (z.B. Phosphatieren, Chromatieren) bzw. mechanische (z.B. Strahlen) Vorbehandlungsverfahren anzuwenden. Aufbauvorschlag: Untergrund: Stahl, Decklack: Schraubensicherungslack ZK 1003, diverse Farben

Allgemeine Verarbeitungsbedingungen und Austrockung

Verarbeitungsbedingungen: oberhalb 10 °C Trocknung: Lufttrocknung bei 20°C Staubtrocken: nach 20 Min. (Trockengrad 1/ DIN 53150) Grifffest: nach 30 Min. (Trockengrad 4/ DIN 53150) Durchgetrocknet: nach 6 Tagen (Pendeldämpfung/ ISO 1522) Ofentrocknung: bis 50°C möglich (Objekttemperatur) Dauergebrauchstemperatur: max. 130°C (ausgenommen bei Zink und verzinkten Untergründen)

Temperatur-Beständigkeit von ZK1003 für alle Farben

Im Minusbereich: Nach einer Woche der Temperaturwechselbelastung von +20°C (über Nacht) und -20°C (8 Std. tagsüber) und anschließenden Lagerung von 3 Wochen bei -20°C haben wir geringe Haftungsverluste festgestellt. Auf Grund dieser Ergebnisse können wir die Temperaturbeständigkeit bis -20°C nicht bestätigen und empfehlen den Schraubensicherungslack nicht unter -10°C einzusetzen. Im Einzelfall können eigene Prüfungen notwendig sein, da Art und Beschaffenheit des Untergrundes sowie der Einsatzbereich von ZK 1003 zu berücksichtigen ist und in Laborprüfungen nicht nachgestellt werden kann. Dauergebrauchstemperatur: max. 130°C (ausgenommen bei Zink und verzinkten Untergründen).

Bitte füllen Sie das Formular aus, um ein Sicherheitsdatenblatt DE anzufordern.

Vielen Dank für Ihre Anfrage. Gerne geben wir Ihnen unseren aktuellen Produktpreis an. Bitte schreiben Sie per E-Mail oder füllen Sie das folgende Formular aus.

Wir werden Sie in Kürze kontaktieren.

Lackfabrik Bäder GmbH & Co KG

Dieselstraße 34

73734 Esslingen

Deutschland

Tel: +49 (0) 711 381607

Zolltarifnummer: 3208 10 90

LIEFERBEDINGUNG

Die Lieferung erfolgt, vorbehaltlich Verfügbarkeit, innerhalb Deutschlands in 2-3 Werktagen, innerhalb der EU in 4-7 Werktagen oder natürlich termingerecht.

Unser Schraubensicherungslack wird in einer Alutube 50g=46ml Inhalt in einer eigenen Faltschachtel geliefert.

SCHRAUBENSICHERUNGSLACK ZK1003

Der Schraubensicherungslack ZK1003 von

H. August Müller ist seit über 50 Jahren auf dem Markt. Wir beliefern deutsche und internationale Produktionsstandorte von kleinen, mittleren, großen und globalen Industrieunternehmen. In all den Jahren, in denen wir unsere Produkte auf dem Markt anbieten, haben wir uns durch unsere schnelle, zuverlässige und tadellose Lieferung einen hervorragenden Ruf bei unseren Kunden aufgebaut. Unser Schraubensicherungslack ZK1003 ist DAS Hilfsmittel zum Markieren und Versiegeln und es können Manipulationen nachgewiesen werden. Der ZK1003 wird unter anderem an Schraub-, Stecker- und Gehäuseanschlüssen in der Automobil- und Stahlindustrie, Luftfahrt, Elektronik, Maschinenbau und Feinmechanik eingesetzt.

Wir verkaufen folgende Farben:

Schraubensicherungslack ZK1003 – rapsgelb RAL 1021

Schraubensicherungslack ZK1003 – signalrot RAL 3001

Schraubensicherungslack ZK1003 – lichtblau RAL 5012

Schraubensicherungslack ZK1003 – grasgrün RAL 6010

Schraubensicherungslack ZK1003 – eisengrau RAL 7011

Kennzeichnungslack

Verkehrstechnik, Elektronik, Elektrotechnik

Versiegeln

Luftfahrttechnik Energie, Windkraft, Telekommunikation

Sicherungslacke

Autoindustrie, Maschinenbau, Feinmechanik

Häufig gestellte Fragen

Das sind die häufigsten Fragen, die unsere Kunden stellen:

Wo/Wie wird unser Lack eingesetzt?

Wie lagert man den ZK1003 am besten?

Für welche Untergründe wird der ZK1003 benutzt?

Allgemeine Verarbeitungsbedingungen/Austrockung

Temperatur-Beständigkeit von ZK1003 (alle Farben):

Lackfabrik Bäder GmbH & Co KG

Dieselstraße 34

73734 Esslingen

Deutschland

Tel: +49 (0) 711 381607

Bitte füllen Sie das Formular aus, um ein Sicherheitsdatenblatt DE anzufordern.

Vielen Dank für Ihre Anfrage. Gerne geben wir Ihnen unseren aktuellen Produktpreis an. Bitte schreiben Sie per E-Mail oder füllen Sie das folgende Formular aus.

Wir werden Sie in Kürze kontaktieren.